Flexibility for Unlimited Potential

The new generation of Kbiotech benchtop bioreactor and fermenter controllers are designed to be assembled from individual modules. This allows for maximum flexibility and easy customization as the modules can be combined to create a bioreactor system that is tailored to your specific development and application needs.

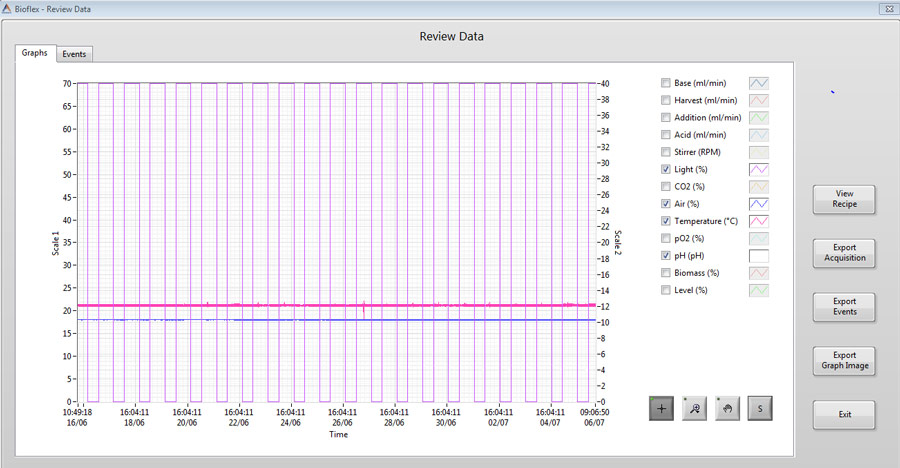

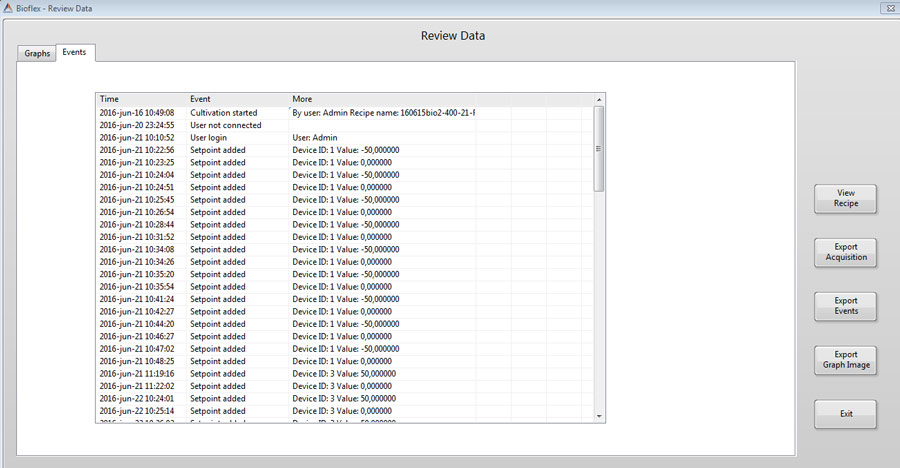

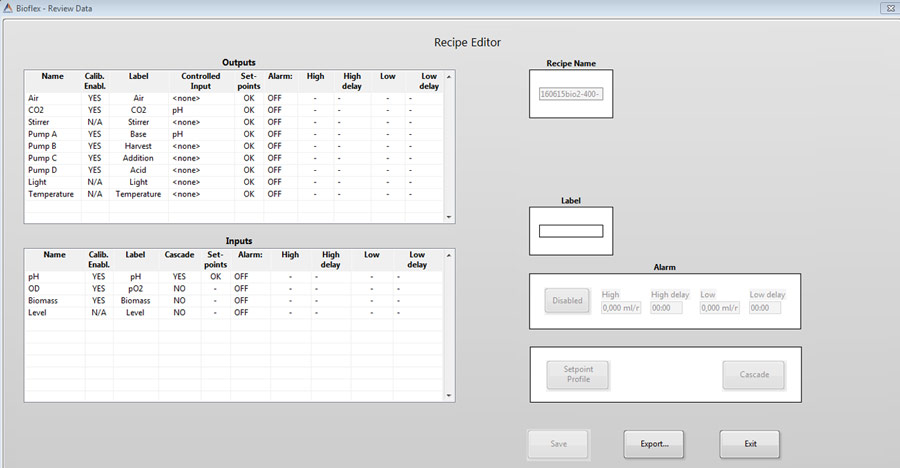

Combined with our Bioflex software platform, these bioreactor systems are easily scaled for more demanding development tasks of to larger vessel volumes.

Available Individual Modules:

- Control module

Operate 1 to 4 vessels

probes interface of pH, DO, Temperature, Antifoam, Level, Turbidity biomass, Capacitance, Glucose, Redox, Pressure, Conductivity - Pump module

Variable speed peristaltic pumps up to 8 per module. - Gas mix module

Mass Flow Control or rotameter design for up to 8 different gases including mixing and set up for multiple spargers - Thermo chiller module for temperature regulation, heating and cooling capabilities

- Ancillary instruments; Off-Gas Analysis: O2, CO2, N2, H2, CH4, CO, Ethanol

Weight: Fed-Batch, Continuous

Automated Sampling

Key Features

- FPGA Industrial Controller with superior computing power to process numerous data in real time

- Bioflex Advanced SCADA Software, an innovative web server to monitor and control from 1 to 12-24 bioreactors online

- Ethernet and OPC UA connectivity

- Expandability of individual modules for managing from 1 to 12 bioreactors in parallel

- Ready on board I/O’s for easy servicing of online analytics: Biomass sensors, Gas analyzers, Mass Balance, automated samplers and online multi-assay Analyzers

- The pump module can house up to 6 variable-speed stepper pumps per bioreactor and the number of modules can be expanded

- The gases module can house up to 8 Flow meters or Mass flow controllers per bioreactor and the number of modules can be expanded

- Individual vessels temperature controlled

- Validatable for GLP and GMP use

- Sales and service available worldwide

Interchangeable vessels, total volume

Benchtop Compact control units allow Glass, Disposable and Steel vessel that can be easily swapped out for another. This can be useful for a variety of purposes, such as

- Portability and Versatility

Interchangeable vessels can be used for a variety of different tasks, depending on the process requirements and scalability. This can save you from having to buy and carry multiple control unit for each vessels. - Efficiency

Interchangeable vessels can make your work more efficient, as you can quickly swap out the vessel that you need without having to stop and change control unit.

Choose the type of vessel that’s right for you:

We produce autoclavable glass vessels for various applications from animal cell cultures, insect cells, stem cells, bacterial fermentations, yeasts, biogas, and many other applications. Various accessories are also available based on the type of application and process such as marine, pitched blade, axial, radial, rushton impellers, safe sampler and perfusion systems, sterile liquids and gases additions for feedbatch and continuous application.

KBiotech SUB Single-Use vessels allow scalable cell culture and fermentation from research to production. These rigid-wall stirred-tank single-use vessels have been specifically designed and optimized for cultivation suspended, adherent cells, microbial, bacterial fermentation in batch, feed batch and continuous / perfusion culture.

Water jacketed and Single Wall Vessels Volumes: 300ml, 500ml, 1L, 3L, 10L, 30L

KBiotech offer pre-assembled SIP bioreactors packages or custom made solutions based on detailed requirements. Our laboratory SIP bioreactors are designed to guarantee better performances and improve process conditions like scaling up or scaling down, mixing and oxygen transfer, heating/cooling thermal transfer, sterility and cleaning procedures to optimize manufacturing time and costs saving.

Water jacketed and single wall Steel vessels Volumes: 500ml-1-3-5-7-10-15-20-30-40-50 Liters

Applications

Cell applications:

- Cell therapy

- Gene therapy

- Regenerative Medicine

- CART-cell

Biopharmaceutical applications:

- Cell Line Development

- Media optimization

- Process scale-down

- Biosimilars

- Monoclonal Antibodies

- Vaccines

- mRNA Production

- Plasma and Blood derivates

- Proteins

Basic or Advanced Research & Development:

- Microbial, yeasts and fungi fermentation,

- Culturing animal cells, insect cells, stem cells,

- Plant cells and Algae

Alternative foods:

- Dairy products

- Synthetic meat cell culturing

- Food ingredients

- Plant cell culture

Renewables:

- Biofuels

- Bioplastic

- Biopolymers

- Biogas

- Biomolecules

- Wastewater remediation

Intelligent HMI-PC Interface with onboard BIOFLEX TM Software to fully monitor, control and supervise your bioprocess without the need to purchase additional devices or software for data processing.

Technical data of the modules

- Power supply: 120 – 240 (±10 %) V, 50/60 Hz, 10 A, Single Phase

- Communication: USB, Ethernet, OPC UA (SCADA, IP Network)

- User Interface: Touchscreen or desktop PC from 10″ to 22″ screen size available

- Dimensions: (W × D × H): 28.0 × 40.0 × 60.0 cm / 11 × 15.75 × 24.4 inches

- Weight w/o accessories: 15.5 kg / 34.1 lbs

Online process analyzers to improve product development and quality control monitoring

Online analyzers are instruments that are used to measure the physical and chemical properties of a process such as Biomass, Gas analysis, nutrients and dissolved CO2 in real time. They are typically installed directly in the process line or directly in contact with the liquid, and provide continuous data on the composition and quality of the bioprocess and to ensure compliance with Good Manufacturing Practices. The KBiotech Online analyzers offer a number of advantages over traditional laboratory analysis methods, including:

Real-Time Data

Online analyzers provide continuous data on the composition and quality of the process, which allows operators to make immediate adjustments to the process if necessary.

Accuracy

Online analyzers are typically very accurate, and can detect changes in the process that would be difficult or impossible to detect with traditional laboratory analysis methods.

Efficiency

Online analyzers can save time and money by eliminating the need for manual sampling and laboratory analysis.

KB-Ferm Gas Analyzer

KG-Ferm KBiotech Gas analyzer for online monitoring of exhaust gases for the calculation of respiratory quotients and metabolic activity. Available gases: O2, CO2, CH4, H2, Ethanol. Contact us for more details.

All online analyzers can be connected to our SCADA Bioflex Software for online data acquisition, feedback control and predictive data analysis for process optimization and risk-based actions, PAT compliance.

Online Biomass Sensors

KB-Dencitee Total cell density sensor, in-situ measurement of total cell density using transmittance and reflectance of near-infrared light in low and high cell density applications.

KB-Incyte-VBC real-time monitoring of viable cell biomass based on capacitance measurement for cell culture and fermentation process.

Analyzers connectivity for feedback control and process optimization

All online analyzers can be connected to our SCADA Bioflex Software for online data acquisition, feedback control and predictive data analysis for process optimization and risk-based actions, PAT compliance.