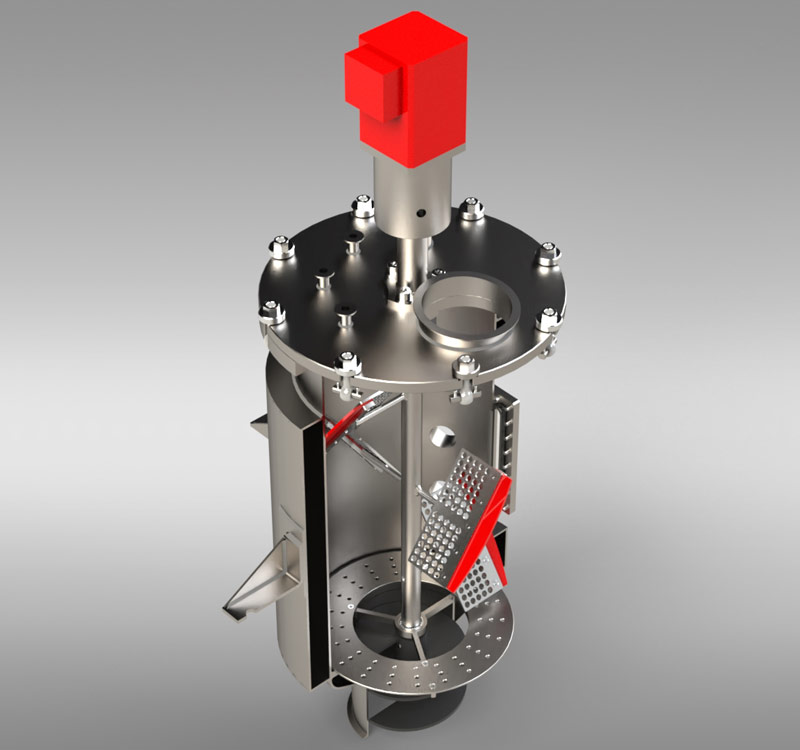

Process and preparation vessels for liquids, semi-solid and solids compounds

Formulation, storage and filling vessel

Vessels Volume from 3 to 5000 liters as well as custom fit solutions.

All vessels can be supplied as stand-alone equipment (stationery or mobile) or as automated process units delivered as fully-functional modules installed on-site which include: agitators, homogenizers, metering and regulating technology, control units, valves and pipe connections. Options for hazardous environments are also available.

Features

- Vessels made of stainless steel AISI 304, 316, 904 and high-alloy, special realizations are also possible

- Customized manufacturing

- Design: Single, double and triple wall design, heatable, insulated

- High quality surface finish: ≤ 0.2 µm, ≤ 0.4 µm, ≤ 0.6 µm, ≤ 0.8 µm

- Heating & Cooling with high degree of temperature control from -20 °C to 200 °C

- Agitation with a selection of trustable mechanical mixers and magnetic couplers with different type of shafts and propellers

- All vessels are engineered to ensure effective Clean-in-Place (CIP) and Sterilize-in-Place (SIP)

- Material traceability of vessel parts and components.

- Full set of DQ, IQ, OQ documentation available

Usage

- Preparation vessel for production of highly sterile products

- Buffer preparation vessel for plasma fractionation

- Media preparation for pharmaceutical, chemical and bio-food

- Vessels for dissolution of solid and semi-solid components.