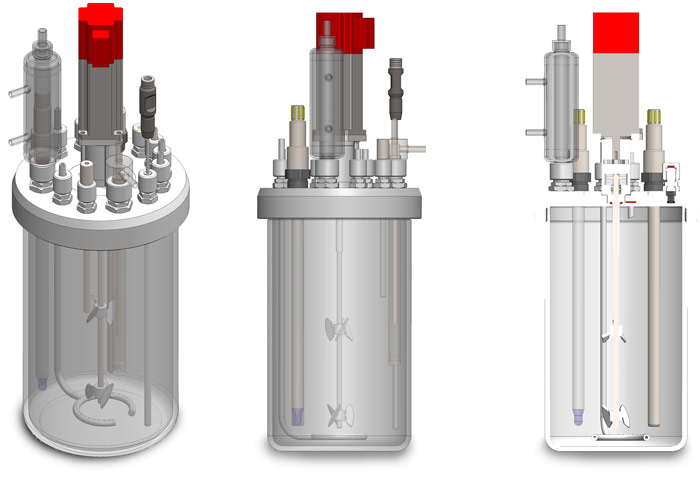

SUB & SUF disposable solutions for cell culture and fermentations

KBiotech have developed an innovative JACKET DESIGN system that allows you to quickly switch from glass to disposable vessels and vice versa. The jacket allows a better regulation of the temperature and it is also possible to integrate our Chiller for optimal control, minimizing water consumption in your lab.

BIO-BOOK Compact and BIO-BOOK UP Modular Controllers are both designed to control your stirred-tank glass or single-use vessels. Our Single-use Bioreactor systems (SUB Disposable) can be used for animal, plant and insect cell cultivation as well as for microbial fermentation.

One or more control towers drive single or parallel culture vessels independently of each other, opening up a new world of flexibility to adapt dynamically to your requirements.

Whether you need to perform batch, fed-batch or perfusion processes for process development, production or preclinical and upscaling studies, KBiotech SUB’s are the ideal benchtop bioreactors for your lab.

Applications

General applications:

- Insect, mammalian, and human suspension cell lines

- Stem cells

- Adherent cells

- Microbial fermentation

Top features

- Configurable, single-use bioreactors with a choice of vessels for cell culture and fermentation from 300ml to 30 litres in volume

- High quality polycarbonate and Nylon components for safe, single-use operations

- High precision E-beam (32 kGy) irradiated in dual polyester foil bags

- SUB vessels head-plate developed to integrate standard pH and PO2 sensors but also accessories such as Biomass, pCO2 and others

- Any Kbiotech SUB vessel is compatible with Compact and Modular controllers for single and parallel operations

- A wide range of impellers, rotation or up-flow/down-flow/axial/radial fluid circulation for various applications

- Available re-usable and single-use sensors for pH and DO

- Universal Brushless motor for disposable and re-usable vessels, whole range from 300 ml to 30 L volume

- Temperature controlled liquid jacket RUJ or SUJ through electrical heating blankets

- Aeration methods such as micro spargers, drilled hole spargers, l-spargers, headspace gas exchange

- Large selection of accessories to configure the vessel to your requirements