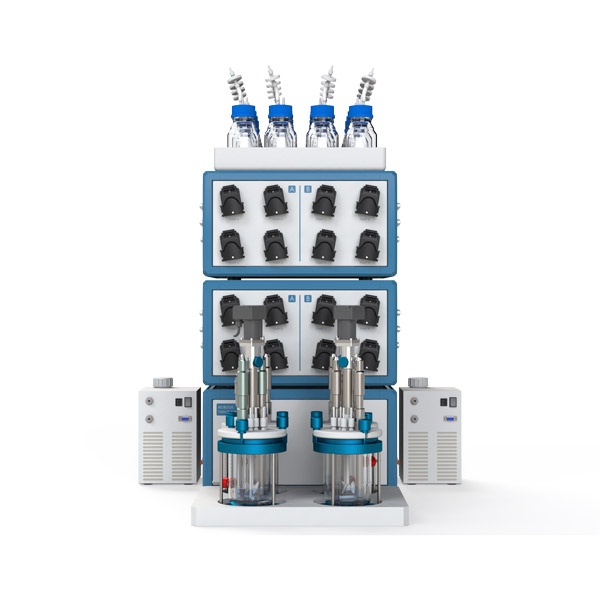

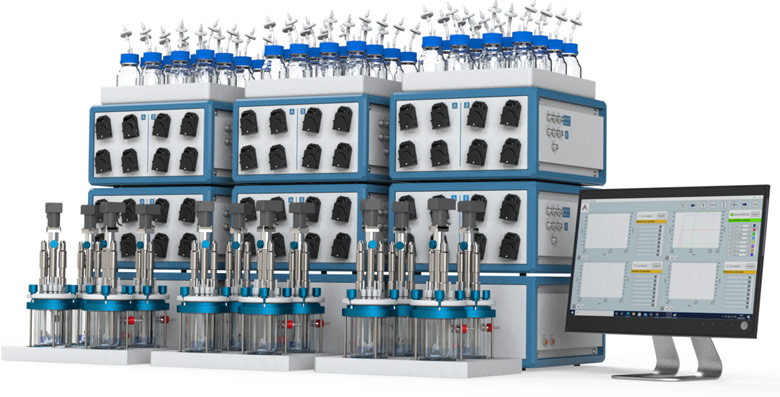

Up to 12-24 parallel vessels

Kbiotech parallel modular bioreactors offer advanced controller functionalities designed to meet demanding requirements in both research and process development, as well as for media optimization and screening studies.

The Kbiotech PARALLEL system features a POWERFUL master control tower with satellite Module for pumps, gas mixing, temperature control and chillers. Thanks to its high flexibility the parallel system can be configured with up to 36 bioreactors, each providing independent control of the applicable culture vessel. Leading master controller technology for advanced data-logging and embedded monitoring applications. Unlimited series I/O modules for custom analogue input, analogue output, digital I/O, counter/timer, CAN measurement and logging system for advanced bioprocesses.

We offer a wide selection of interchangeable Autoclavable and Disposable vessels, from 50 mL to 20 litres volume.

Applications

Biopharmaceutical applications:

- Cell Line Developments

- Media optimization

- Process Intensification

- Biosimilars

- Monoclonal Antibodies

- Vaccines

- mRNA Production

- Plasma and Blood derivates

- Proteins

Cell applications:

- Cell therapy

- Gene therapy

- Regenerative Medicine

- CAR T-cell

Alternative foods:

- Dairy products

- Synthetic cell culturing

- Food ingredients

- Plant cell culture

Renewables:

- Biofuels

- Bioplastic

- Biopolymers

- Biogas

- Biomolecules

- Wastewater remediation

Top features

Our newly engineered control system takes many of our well-proven design features into a new era, offering unprecedented benefits to process development laboratories around the world, including unrivalled capabilities for downscale and upscale modelling of various culture processes and the provision of new levels of power and flexibility.

- The modular design of our systems offers flexible solutions for bioprocess developments for culturing of mammalian, insect and stem cells but also microbial and fungi fermentations at a laboratory scale.

- Our parallel systems have the advantage of accurate controls and automated operations with comprehensive information management.

- Interchangeable vessels: Glass single-wall or jacketed, SUS single-use disposable and lab scale SIP steel vessels

- Highly accurate MFC mass flow controllers for cell culture and microbial fermentation strategies.

- Variable-speed stepper pumps with bi-directional flow for precise addition of liquids up to 0.05 ml / min of accuracy

- OEM solution with third-party instruments integration: biomass sensors, gas analyzers, viable cell counters, metabolite analyzers, HPLC

- (PAT), control units and Software.

- BIOFLEX™ Scada software supports sophisticated process control, comprehensive data and information management and Design of Experiments (DoE).

- Advanced database, embedded report generator provides recipe information, process information, historical batches and cultivation runs.

- Additional features include OPC technology and ability to interface with scientific software packages such as LabVIEW and MATLAB.

- Online maintenance service and support with remote diagnostics.

The Best Heating and Cooling system

The BIO-BOOK controller allows the integration of Kbiotech Bio-Chiller with innovative Peltier technologies and optimal regulation of the temperature from 10°C to 60°C with a high degree of precision up to 0.1°C, as well as substantial savings on water and energy.

Technical data

- Power supply: 120 – 240 (±10 %) V, 50/60 Hz, 10 A, Single Phase

- Water supply: Quick-connect; 10 psig (0.69 barg)

- Communication: USB, Ethernet, Modbus (SCADA, IP Network)

- User Interface: Touchscreen or desktop PC 19”, 22”

- Dimensions of each bioreactor (controller + slave modules): (W × D × H): 31.0 × 45.0 × 67.5 cm / 12.20 × 17.60 × 26.57 inches

- Weight w/o accessories: 36.8 kg / 81 lbs

Online Analyzers available to optimize process control

KG-Ferm KBiotech Gas analyzer for online monitoring of exhaust gases for the calculation of respiratory quotients and metabolic activity. Gases available: O2, CO2, CH4, H2, CO; more available on request.

KB-Incyte-VBC realtime monitoring of viable cell biomass based on capacitance measurement for cell culture and fermentation process.

All online analyzers can be connected to our Bioflex Software for online data acquisition, feedback control and predictive data analysis for process optimization and risk-based actions, PAT compliance.